AC40 emerges

The world’s first AC40 is just weeks away from being shipped to its new base in Auckland, and expectation is ramping up for this most exciting of classes.

Photography by Emirates Team New Zealand

18 July 2022

Advertisement

As the first photos filter through from the build facility of this pocket-rocket that will be used in One Design mode for both the Women’s and Youth events as well as being a testbed for the works teams, it’s an exciting time for the America’s Cup.

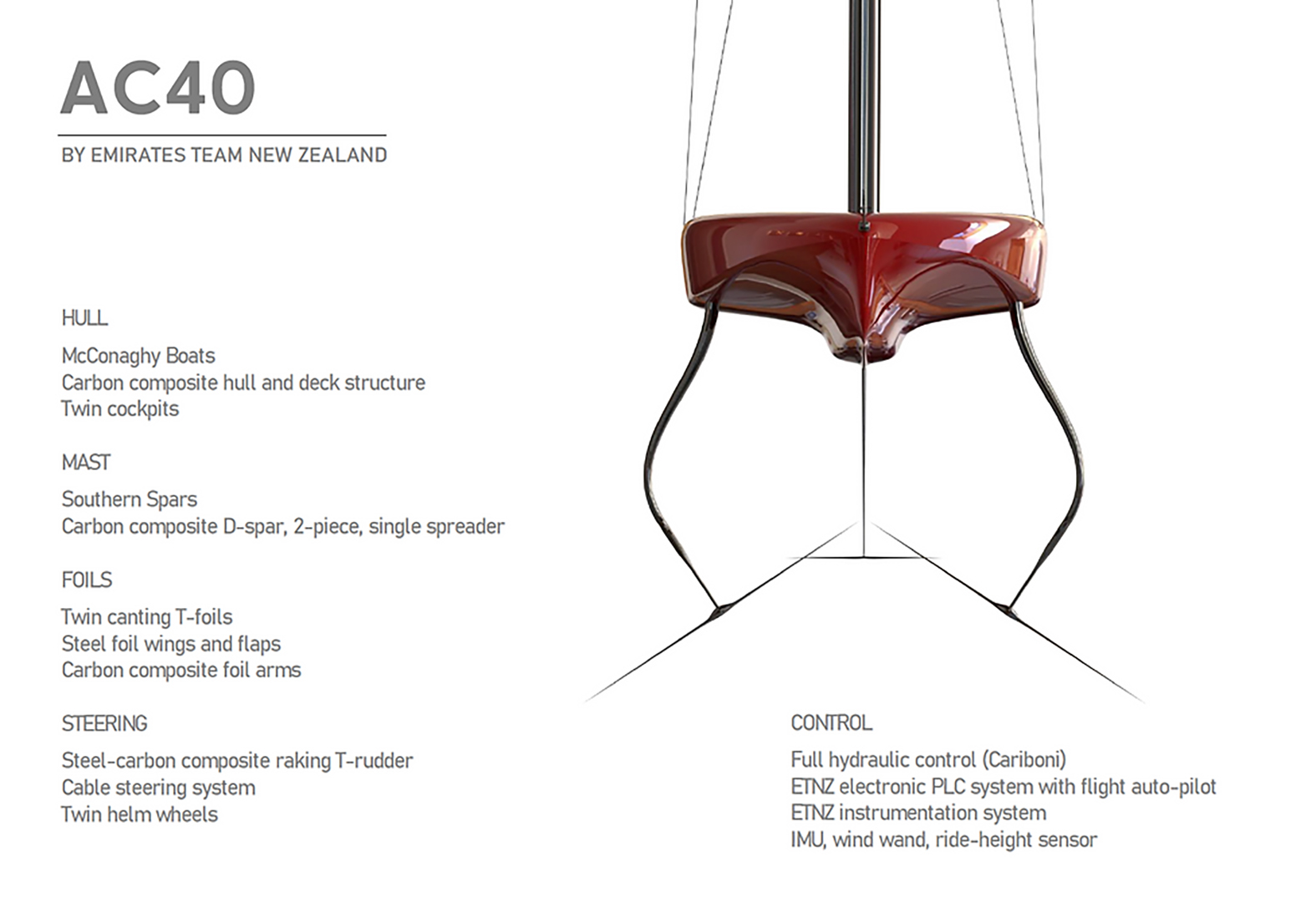

Very much off the boards of the Emirates Team New Zealand Technology & Design Department, the build of the yachts has been overseen by long-standing ETNZ team-member Richard Meacham whilst actually at the McConaghy factory in China, Kiwi Jamie Thompson has been the Project Manager running a dedicated team of builders and craftsmen working shifts around the clock to create this next-generation vessel.

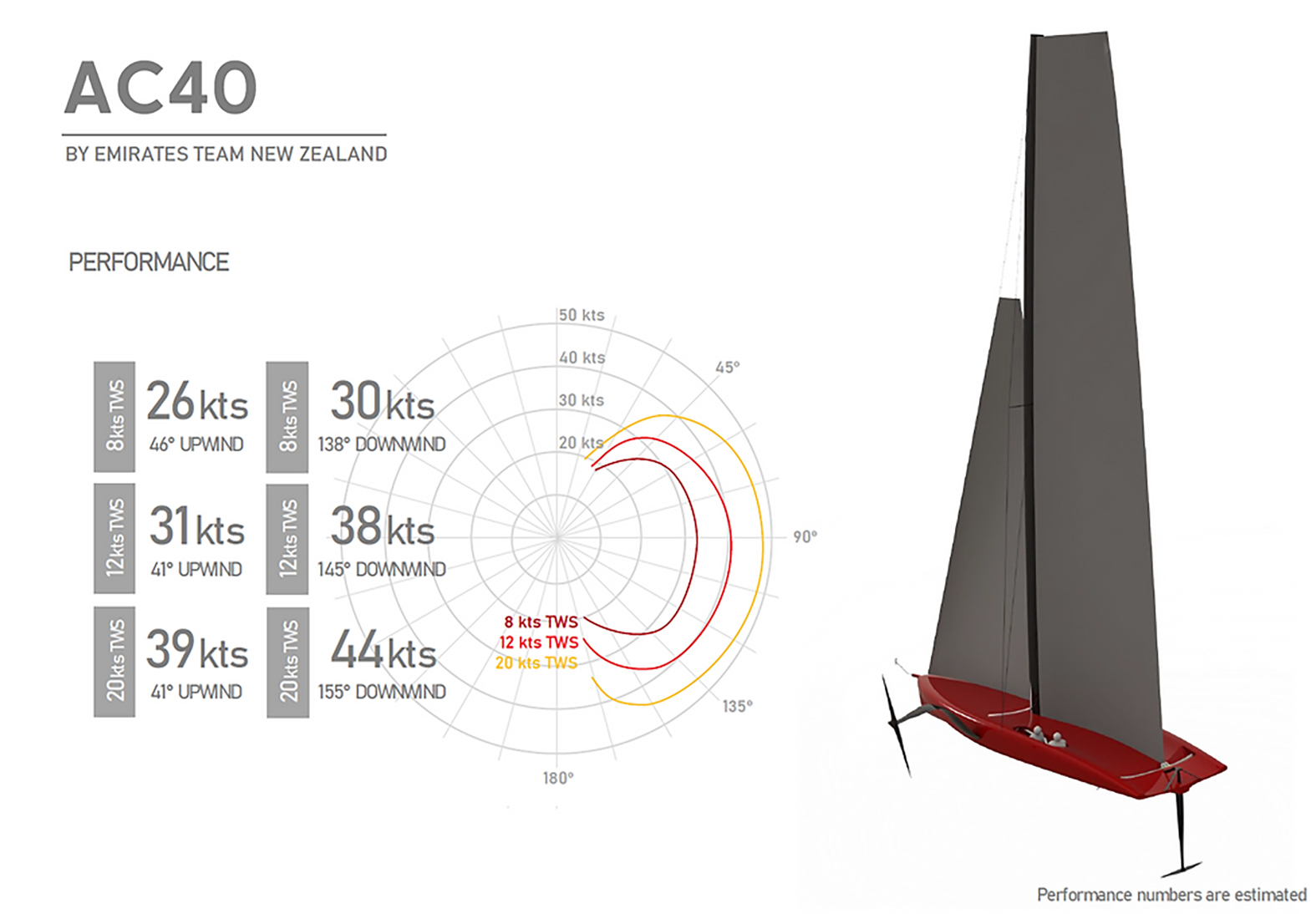

With self-tacking headsails and battery power replacing grinders, the yacht is sailed by two helmsmen and two trimmers. An autopilot control system maintains stable flight.

The AC40 hull shape is based on that of Te Rehutai- but is already a generational step forward incorporating a number of developments learned after the completion of AC36 last year.

Advertisement

In usual America’s Cup fashion, the AC40 design and production timeline has been highly condensed yet achievable due to a global collaboration led by Emirates Team New Zealand design team with Dan Bernasconi and Richard Meacham central to the management of the production process with Mark Evans Group Managing Director of McConaghy Boats.

“While the genesis of the AC40 project coming from the familiar design and innovation of the people within the Emirates Team New Zealand design department we have really had to push the limits by utilising a combination of the best of the New Zealand Marine industry as well as key offshore partnerships,” said Richard Meacham, Platform Coordinator for ETNZ.

“With the likes of Southern Spars and the boat building talent we have at the ETNZ build facility for more specialised elements like the rig and foil arms, we also have a great partnership utilising the production power of an organisation like McConaghy Boats in China for the hulls, decks and fit out as well as North Sails Marine group with the aero package,” said Meacham.

“We didn’t hold back on the design. We took the IP of Te Rehutai (the Cup winning boat from AC36) and translated it into the best 40-footer we could create,” said Dan Bernasconi, Chief Designer of Emirates Team New Zealand.

“It’s a step on in terms of hull form from the Cup winning design of Te Rehutai, that adheres to all the fundamental rule changes implemented for the AC75s and we’re looking at performance estimates way in excess of our training boat, Te Kahu, or any of the other teams’ test mules that they ran in the lead up to AC36,” added Meacham.

Building the hulls away from New Zealand was always going to be controversial to some but Richard Meacham is clearly impressed with the work overseen by Mark Evans and project managed by fellow Kiwi Jamie Thompson at McConaghy’s.

“We assessed the situation early on in the project, but it was clear that that with the scale and timeframe of the overall build of the fleet of AC40s there was a shortage of boat-building labour for the hull builds in New Zealand, so we had to look overseas. McConaghy’s have been fantastic and very hard driving, but the key has been the Kiwi design and technology influence all the way through the process.”

Indeed, the hull, foil arms, rudders, mechatronics, hydraulics, and programmable logic controllers have all come directly from ETNZ’s design teams with the foil arms and rudders being created at ETNZ’s build facility on Auckland’s North Shore. The boomless, double-skinned sails have been designed in collaboration with North Sails whilst the two-piece masts have been crafted by Southern Spars in Avondale, Auckland.

And while for the Women’s & Youth America’s Cups, the AC40s will be returned to strict one-design for the fleet and match-racing formats recently announced; where the AC40s will really come into their own is as a testing platform for the teams.

However, there are strict parameters and cost reduction measures with stipulations including: a maximum of four custom foil wings and four custom flaps.

Ten custom jibs and four mainsails are permitted to be built. Teams will also be allowed to build just one custom mast in addition to the two-piece supplied as standard.

Down below, the auto-pilot controls the ride height only and can be manipulated, holding the wing at a certain set point below the water. If the teams want to change the pitch angle or trim differently for conditions, then there needs to be manual intervention whilst all foil cant operations during the high-speed manoeuvres are controlled by direct input from the crew.

“One of the guiding principles of both the AC40 and AC75 projects is that they must be sailed, trimmed and set by the crew. Top speeds of the AC40s will be well into the forty-knot mark plus they will be optimised to fly faster and sooner in light airs – the same as with the AC75s,” said Dan Bernasconi.

And one of the big considerations for the AC40 global circuit will be the ease of transportation. Each one will be transported on a custom flat rack which can carry the whole boat and all appendages to save on shipping costs and increase transportation efficiencies.

With the first AC40 boat due to be sailing in the next few months and throughout the New Zealand summer, the subsequent AC40s will be rolling off the production line for the main teams in quick succession, the coming months will be a fascinating period as the boats are brought up to speed and the pathway programs for Women’s & Youth AC sailors confirmed.

The runway to AC37 in Barcelona is now lit.

Advertisement

Advertisement

Advertisement